Researchers reported new progress in the study ofDirect Propane Dehydrogenation

Author: Time:2021-08-11 Click:

Propylene is an important and basic building block in the chemical industry.Propylene isgenerally produced from steam cracking and fluid catalytic cracking (FCC) process.With the rapidly growing demand for propylene,direct propane dehydrogenation (PDH) has become an attractive strategy for propylene production.Pt and CrOxbased catalysts are widely used in industrial PDH process. However, the high cost of Pt, strong toxicity of CrOxstill hinder their wide applications.Therefore, it is desirable to develop alternative catalysts.ZnO based catalystsattract wide attention due to its low-cost and environment-friendly character.

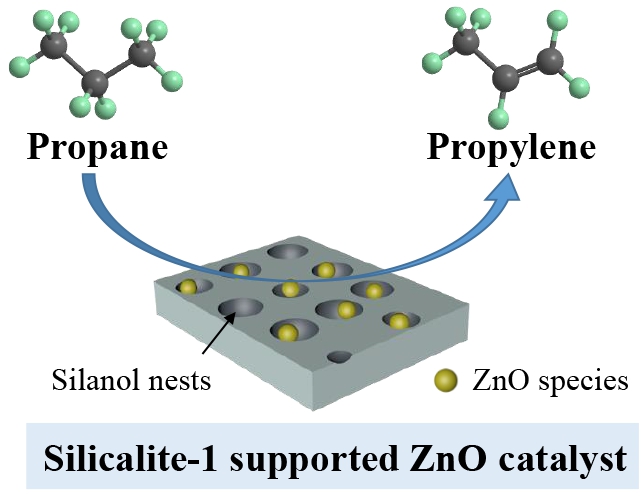

Recently, Prof. Yong Liu and Prof. Wenliang Zhu reported thatSilicalite-1 supported ZnO catalysts exhibited excellentcatalytic performance for PDH reaction.The catalyst with 5 wt% Zn reachedpropane conversion 49% and propylene selectivity around 90% at a space velocity of 5000ml·g-1·h-1. Detailed Characterizations revealthat the high activity and stability can be attributed to the dispersed ZnO species due to theinteraction between silanol nests ofsilicalite-1 support and ZnO species. This study may open a promising wayfor development of highly efficient PDH catalysts.

This work was published inChemCatChem. (Text by Liu Jie)

Silicalite-1 Supported ZnO as an Efficient Catalyst for Direct Propane Dehydrogenation. Jie Liu, Yong Liu*, Hongchao Liu, Yi Fu, Zhiyang Chen, Wenliang Zhu*, ChemCatChem, DOI: 10.1002/cctc.202101069